PWF

matte Lizard Lime

pwf - matte Lizard Lime

INTERIOR DECOR

EVOLV NF32

interior-decor - EVOLV NF32

TECKWRAP

Bond Gold

teckwrap - Bond Gold

INOZETEK

Super Gloss Chalk Grey

inozetek - Super Gloss Chalk Grey

3M

gloss silver chrome

3m - gloss silver chrome

3M

Satin Flip Psychedelic

3m - Satin Flip Psychedelic

3M

Gloss Flip Psychedelic

3m - Gloss Flip Psychedelic

3M

Satin Flip Ghost Pearl

3m - Satin Flip Ghost Pearl

3M

Gloss Flip Ghost Pearl

3m - Gloss Flip Ghost Pearl

3M

Satin Flip Caribbean Shimmer

3m - Satin Flip Caribbean Shimmer

3M

Satin Flip Glacial Frost

3m - Satin Flip Glacial Frost

3M

Gloss Flip Electric Wave

3m - Gloss Flip Electric Wave

3M

Gloss Flip Deep Space

3m - Gloss Flip Deep Space

3M

Satin Flip Volcanic Flare

3m - Satin Flip Volcanic Flare

3M

Matte Red

3m - Matte Red

3M

Gloss Hotrod Red

3m - Gloss Hotrod Red

3M

Gloss Flame Red

3m - Gloss Flame Red

3M

Gloss Dark Red

3m - Gloss Dark Red

3M

Satin Smoldering Red

3m - Satin Smoldering Red

3M

Gloss Dragon Fire Red

3m - Gloss Dragon Fire Red

3M

Matte Red Metallic

3m - Matte Red Metallic

3M

Gloss Red Metallic

3m - Gloss Red Metallic

3M

Satin Vampire Red

3m - Satin Vampire Red

3M

Gloss Cinder Spark Red

3m - Gloss Cinder Spark Red

3M

Matte Orange

3m - Matte Orange

3M

Gloss Bright Orange

3m - Gloss Bright Orange

3M

Gloss Deep Orange

3m - Gloss Deep Orange

3M

Gloss Burnt Orange

3m - Gloss Burnt Orange

3M

Satin Canyon Copper

3m - Satin Canyon Copper

3M

Gloss Liquid Copper

3m - Gloss Liquid Copper

3M

Gloss Fiery Orange

3m - Gloss Fiery Orange

3M

Gloss Lucid Yellow

3m - Gloss Lucid Yellow

3M

Gloss Bright Yellow

3m - Gloss Bright Yellow

3M

Gloss Sunflower

3m - Gloss Sunflower

3M

Satin Bitter Yellow

3m - Satin Bitter Yellow

3M

Gloss Lemon Sting

3m - Gloss Lemon Sting

3M

Gloss Light Green

3m - Gloss Light Green

3M

Satin Apple Green

3m - Satin Apple Green

3M

Gloss Green Envy

3m - Gloss Green Envy

3M

Gloss Kelly Green

3m - Gloss Kelly Green

3M

Matte Pine Green Metallic

3m - Matte Pine Green Metallic

3M

Matte Military Green

3m - Matte Military Green

3M

Shadow Military green

3m - Shadow Military green

3M

Gloss Atomic Teal

3m - Gloss Atomic Teal

3M

Satin Ocean Shimmer

3m - Satin Ocean Shimmer

3M

Satin Key West

3m - Satin Key West

3M

Gloss Sky Blue

3m - Gloss Sky Blue

3M

Matte Riviera Blue

3m - Matte Riviera Blue

3M

Matte Blue Metallic

3m - Matte Blue Metallic

3M

Gloss Blue Metallic

3m - Gloss Blue Metallic

3M

Satin Perfect Blue

3m - Satin Perfect Blue

3M

Gloss Intense Blue

3m - Gloss Intense Blue

3M

Gloss Blue Fire

3m - Gloss Blue Fire

3M

Gloss Cosmic Blue

3m - Gloss Cosmic Blue

3M

Gloss Blue Raspberry

3m - Gloss Blue Raspberry

3M

Gloss Deep Blue Metallic

3m - Gloss Deep Blue Metallic

3M

Matte Slate Blue Metallic

3m - Matte Slate Blue Metallic

3M

Gloss Ice Blue

3m - Gloss Ice Blue

3M

Gloss Glacier Grey

3m - Gloss Glacier Grey

3M

Gloss Midnight Blue

3m - Gloss Midnight Blue

3M

Gloss Boat Blue

3m - Gloss Boat Blue

3M

Matte Indigo

3m - Matte Indigo

3M

Gloss Plum Explosion

3m - Gloss Plum Explosion

3M

Gloss Wicked

3m - Gloss Wicked

3M

Gloss Hot Pink

3m - Gloss Hot Pink

3M

Gloss Fierce Fuchsia

3m - Gloss Fierce Fuchsia

3M

Matte Black

3m - Matte Black

3M

Dead Matte Black

3m - Dead Matte Black

3M

Matte Deep Black

3m - Matte Deep Black

3M

Matte Black metallic

3m - Matte Black metallic

3M

Matrix Black

3m - Matrix Black

3M

Shadow Black

3m - Shadow Black

3M

Carbon Fiber Black

3m - Carbon Fiber Black

3M

Brushed Black Metallic

3m - Brushed Black Metallic

3M

Satin Black

3m - Satin Black

3M

Gloss Black

3m - Gloss Black

3M

Black gloss metallic

3m - Black gloss metallic

3M

Satin Gold Dust Black

3m - Satin Gold Dust Black

3M

Gloss Black Rose

3m - Gloss Black Rose

3M

Gloss Ember Black

3m - Gloss Ember Black

3M

Gloss Galaxy Black

3m - Gloss Galaxy Black

3M

Satin White Aluminum

3m - Satin White Aluminum

3M

Gloss White Aluminium

3m - Gloss White Aluminium

3M

Brushed Aluminium

3m - Brushed Aluminium

3M

Gloss Storm Grey

3m - Gloss Storm Grey

3M

Satin Battleship Gray

3m - Satin Battleship Gray

3M

Gloss Sterling Silver

3m - Gloss Sterling Silver

3M

Matte Silver

3m - Matte Silver

3M

Carbon Fiber Anthracite

3m - Carbon Fiber Anthracite

3M

Brushed Steel

3m - Brushed Steel

3M

Gloss Anthracite

3m - Gloss Anthracite

3M

Satin Thundercloud

3m - Satin Thundercloud

3M

Matte Grey Aluminium

3m - Matte Grey Aluminium

3M

Brushed Titanium

3m - Brushed Titanium

3M

Matte Charcoal Metallic

3m - Matte Charcoal Metallic

3M

Gloss Charcoal Metallic

3m - Gloss Charcoal Metallic

3M

Matte Dark Grey

3m - Matte Dark Grey

3M

Satin Dark Grey

3m - Satin Dark Grey

3M

Matte White

3m - Matte White

3M

Satin white

3m - Satin white

3M

Gloss White

3m - Gloss White

3M

Carbon Fiber White

3m - Carbon Fiber White

3M

Satin Frozen Vanilla

3m - Satin Frozen Vanilla

3M

Gloss White Gold Sparkle

3m - Gloss White Gold Sparkle

3M

Satin Pearl White

3m - Satin Pearl White

3M

Gloss Light Ivory

3m - Gloss Light Ivory

3M

Satin Caramel Luster

3m - Satin Caramel Luster

3M

Gloss Gold Metallic

3m - Gloss Gold Metallic

3M

Matte Copper Metallic

3m - Matte Copper Metallic

3M

Matte brown Metallic

3m - Matte brown Metallic

3M

Satin Komodo Green

3m - Satin Komodo Green

Avery

Satin-Hope-green

avery - Satin-Hope-green

Avery

Matte Olive Green

avery - Matte Olive Green

Avery

Satin Dark Basalt

avery - Satin Dark Basalt

Avery

Gloss Rock Grey

avery - Gloss Rock Grey

Avery

Satin Safari gold

avery - Satin Safari gold

Avery

Gloss sand Sparkle

avery - Gloss sand Sparkle

Avery

Gloss Metallic Spark

avery - Gloss Metallic Spark

Avery

Gloss Metallic Magnetic Burst

avery - Gloss Metallic Magnetic Burst

Avery

Gloss Metallic Radioactive

avery - Gloss Metallic Radioactive

Avery

Gloss Eclipse Metallic

avery - Gloss Eclipse Metallic

Avery

Glossy Cloudy Blue

avery - Glossy Cloudy Blue

Avery

Glossy Light Pistachio

avery - Glossy Light Pistachio

Avery

Glossy Sea-Breeze Blue

avery - Glossy Sea-Breeze Blue

Avery

Glossy Smoky Blue

avery - Glossy Smoky Blue

Avery

Satin Lightning Ridge

avery - Satin Lightning Ridge

Avery

Glossy Lightning Ridge

avery - Glossy Lightning Ridge

Avery

Satin Fresh Spring gold silver

avery - Satin Fresh Spring gold silver

Avery

Glossy Fresh Spring gold:silver

avery - Glossy Fresh Spring gold:silver

Avery

Satin Urban Jungle silver green

avery - Satin Urban Jungle silver green

Avery

Glossy Urban Jungle silver:green

avery - Glossy Urban Jungle silver:green

Avery

Satin Roaring Thunder blue red

avery - Satin Roaring Thunder blue red

Avery

Glossy Roaring Thunder blue red

avery - Glossy Roaring Thunder blue red

Avery

Satin Rushing Riptide cyaan purple

avery - Satin Rushing Riptide cyaan purple

Avery

Glossy Rushing Riptide cyaan purple

avery - Glossy Rushing Riptide cyaan purple

Avery

Satin Rising Sun red gold

avery - Satin Rising Sun red gold

Avery

Glossy Rising Sun red gold

avery - Glossy Rising Sun red gold

Avery

Glossy Ambulance Yellow

avery - Glossy Ambulance Yellow

Avery

Glossy Yellow

avery - Glossy Yellow

Avery

Satin yellow

avery - Satin yellow

Avery

Glossy Dark Yellow

avery - Glossy Dark Yellow

Avery

Glossy pearl Gold Orange

avery - Glossy pearl Gold Orange

Avery

Matte Metallic Blaze Orange

avery - Matte Metallic Blaze Orange

Avery

Glossy Orange

avery - Glossy Orange

Avery

Satin Orange

avery - Satin Orange

Avery

Matte Orange

avery - Matte Orange

Avery

Gloss Cardinal Red

avery - Gloss Cardinal Red

Avery

Satin Cardinal Red

avery - Satin Cardinal Red

Avery

Gloss Carmine Red

avery - Gloss Carmine Red

Avery

Satin Carmine Red

avery - Satin Carmine Red

Avery

Gloss Red

avery - Gloss Red

Avery

Gloss Soft Red

avery - Gloss Soft Red

Avery

Red diamond

avery - Red diamond

Avery

Gloss pearl red

avery - Gloss pearl red

Avery

Matte Metallic Cherry

avery - Matte Metallic Cherry

Avery

Matte Metallic Garnet Red

avery - Matte Metallic Garnet Red

Avery

Gloss Burgundy

avery - Gloss Burgundy

Avery

Satin Bubblegum pink

avery - Satin Bubblegum pink

Avery

Matte Metallic Pink

avery - Matte Metallic Pink

Avery

satin metallic purple

avery - satin metallic purple

Avery

Matte Metallic Purple

avery - Matte Metallic Purple

Avery

Purple diamond

avery - Purple diamond

Avery

Matte Metallic Powder Blue

avery - Matte Metallic Powder Blue

Avery

Matte Metallic Frosty Blue

avery - Matte Metallic Frosty Blue

Avery

Gloss Light Blue

avery - Gloss Light Blue

Avery

satin light blue

avery - satin light blue

Avery

Bright Blue Gloss Metallic

avery - Bright Blue Gloss Metallic

Avery

Blue diamond

avery - Blue diamond

Avery

Gloss Intense Blue

avery - Gloss Intense Blue

Avery

Gloss Blue

avery - Gloss Blue

Avery

Gloss Dark Blue

avery - Gloss Dark Blue

Avery

satin dark blue

avery - satin dark blue

Avery

Matte Metallic Brilliant Blue

avery - Matte Metallic Brilliant Blue

Avery

Matte Metallic Blue

avery - Matte Metallic Blue

Avery

Matte Metallic Night Blue

avery - Matte Metallic Night Blue

Avery

Gloss Indigo Blue

avery - Gloss Indigo Blue

Avery

Gloss Dark Blue Metallic

avery - Gloss Dark Blue Metallic

Avery

Glossy Pearl light green

avery - Glossy Pearl light green

Avery

Gloss Lime Green

avery - Gloss Lime Green

Avery

Gloss Grass Green

avery - Gloss Grass Green

Avery

satin grass green

avery - satin grass green

Avery

Matte Metallic Apple Green

avery - Matte Metallic Apple Green

Avery

Gloss pearl Dark Green

avery - Gloss pearl Dark Green

Avery

Gloss Dark Green

avery - Gloss Dark Green

Avery

Satin Khaki Green

avery - Satin Khaki Green

Avery

Matte Khaki Green

avery - Matte Khaki Green

Avery

Carbon Fiber White

avery - Carbon Fiber White

Avery

Gloss White

avery - Gloss White

Avery

Satin White

avery - Satin White

Avery

Matte White

avery - Matte White

Avery

Gloss pearl white

avery - Gloss pearl white

Avery

Satin pearl white

avery - Satin pearl white

Avery

White diamond

avery - White diamond

Avery

Silver Gloss metallic

avery - Silver Gloss metallic

Avery

Gloss Metallic Quick Silver

avery - Gloss Metallic Quick Silver

Avery

Satin Silver Metallic

avery - Satin Silver Metallic

Avery

Matte Metallic Silver

avery - Matte Metallic Silver

Avery

Silver diamond

avery - Silver diamond

Avery

Brushed Aluminium

avery - Brushed Aluminium

Avery

Gloss Grey

avery - Gloss Grey

Avery

Satin grey

avery - Satin grey

Avery

Brushed Titanium

avery - Brushed Titanium

Avery

Matte Metallic Anthracite

avery - Matte Metallic Anthracite

Avery

Gloss Dark Grey

avery - Gloss Dark Grey

Avery

Matte Dark Grey

avery - Matte Dark Grey

Avery

Matte Metallic Gunmetal

avery - Matte Metallic Gunmetal

Avery

Matte Metallic Charchoal

avery - Matte Metallic Charchoal

Avery

Brushed Steel

avery - Brushed Steel

Avery

Gloss metallic Grey

avery - Gloss metallic Grey

Avery

Carbon Fiber Black

avery - Carbon Fiber Black

Avery

Gloss Black

avery - Gloss Black

Avery

Satin Black

avery - Satin Black

Avery

Matte Black

avery - Matte Black

Avery

Gloss Metallic Black

avery - Gloss Metallic Black

Avery

Brushed Black

avery - Brushed Black

Avery

Gloss Gold metallic

avery - Gloss Gold metallic

Avery

Diamond Amber

avery - Diamond Amber

Avery

Brushed Bronze

avery - Brushed Bronze

Avery

Matte metallic Brown

avery - Matte metallic Brown

Avery

Gloss Metallic Brown

avery - Gloss Metallic Brown

Avery

Satin Rock Grey Metallic

avery - Satin Rock Grey Metallic

Avery

Rose Gold Chrome

avery - Rose Gold Chrome

Avery

Violet Chrome

avery - Violet Chrome

Avery

Matt silver Chrome

avery - Matt silver Chrome

Avery

silver Chrome

avery - silver Chrome

Avery

Gold Chrome

avery - Gold Chrome

Avery

Red Chrome

avery - Red Chrome

Avery

Blue Chrome

avery - Blue Chrome

Avery

Black Chrome

avery - Black Chrome

KPMF

Satin Stealth Tundra

kpmf - Satin Stealth Tundra

KPMF

Matte Black

kpmf - Matte Black

KPMF

Metro Matte Violaceous Blue

kpmf - Metro Matte Violaceous Blue

Custom Colors

Aspen snowcamo

customcolors - Aspen snowcamo

Custom Colors

custom printed

customcolors - custom printed

Custom Colors

discontinued color

customcolors - discontinued color

Custom Colors

muttha purple

customcolors - muttha purple

Custom Colors

Carbon PP2 Glossy

customcolors - Carbon PP2 Glossy

Custom Colors

Carbon PP2 Matte

customcolors - Carbon PP2 Matte

Oracal

Aquamarine

oracal - Aquamarine

Oracal

Papyrus

oracal - Papyrus

Oracal

Charcoal Metallic

oracal - Charcoal Metallic

Oracal

Champagne Metallic

oracal - Champagne Metallic

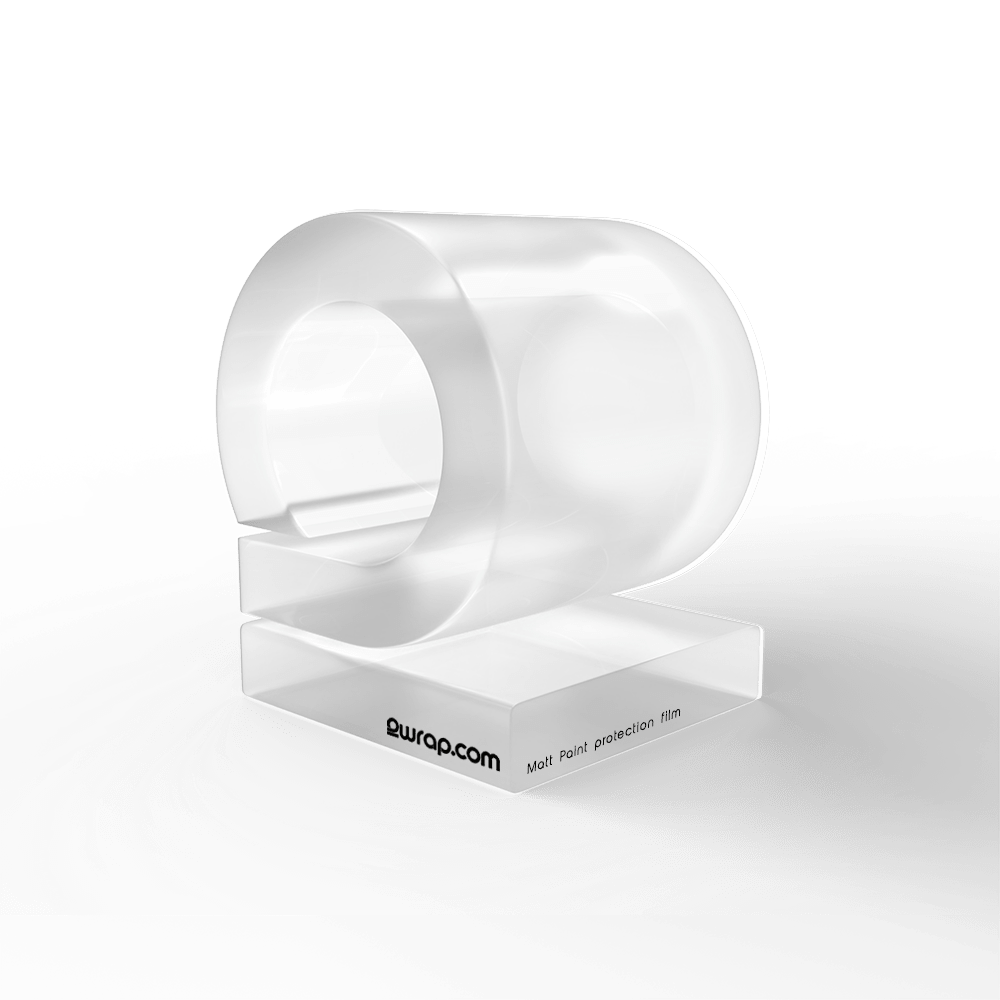

Paint Protection Film

Premiumshield Glossy

paint-protection-film - Premiumshield Glossy

Paint Protection Film

Premiumshield Matt

paint-protection-film - Premiumshield Matt

APA / EVOLV

Gloss Supercandy Burgundy

apa - Gloss Supercandy Burgundy

APA / EVOLV

Black Velvet

apa - Black Velvet

APA / EVOLV

Black Olive

apa - Black Olive

oops! No Colors found. Try another filter or Reset filter

Referal Letter Aquila Yacht

Referal Letter Aquila Yacht carwrap simulator

carwrap simulator 3D CARWRAP CONFIGURATOR

3D CARWRAP CONFIGURATOR