What Is Colored Paint Protection Film? Your Complete Guide to PPF Options and Benefits

Colored paint protection film (PPF) is a pigmented thermoplastic polyurethane (TPU) membrane that pairs durable surface defense with reversible visual customization — protection and style without changing your factory paint. This guide breaks down how colored PPF works, why collectors and luxury owners choose it over repainting, and how it compares to vinyl wraps and clear PPF. We cover the material science (TPU and self‑healing topcoats), finish choices and maintenance, brand differences, and the installation and cost factors that determine long‑term value. Whether you’re researching colored paint protection film, ppf colors, TPU paint protection film, or professional colored PPF installation, this article maps the practical choices so you can decide what’s right for your daily driver, high‑end car, or fleet.

What Is Colored Paint Protection Film and How Does It Enhance Vehicle Protection?

Colored PPF is a pigmented or finished TPU layer applied over a car’s paint to absorb and dissipate impact forces while shielding against UV and chemical damage. TPU gives the film elasticity and strength; a cured topcoat adds hydrophobic properties and self‑healing behavior so light scratches often disappear as the polymer relaxes. The full protective stack — TPU film, pressure‑sensitive adhesive, and topcoat — forms a sacrificial barrier against rock chips, scuffs, and contaminants, preserving the factory finish. At the same time, integrated pigment and finishes provide color and texture that are removable, offering reversible customization without repainting.

What defines colored PPF and its role in car customization?

Colored PPF is made by embedding pigment or a finished surface directly into the TPU film rather than painting the car. That makes it removable and nondestructive to factory paint, so owners can change color or finish temporarily and later restore the original finish. Typical applications include accent panels, partial wraps for contrast, or full‑vehicle color changes — all reversible, which is especially valuable for collectors and exotic‑car owners who want bold looks without permanently altering provenance.

How does colored PPF protect against scratches, chips, and UV damage?

Protection comes from TPU’s mechanical properties—its elasticity and tensile strength—combined with a chemically resistant topcoat. The self‑healing topcoat uses polymer flow and heat activation to close fine abrasions, while the film’s greater thickness (compared with most vinyl) helps absorb rock impacts and prevent chips. UV stabilizers in both the TPU and topcoat reduce yellowing and color shift over time. Together these elements provide a layered defense: impact absorption, abrasion resistance, and environmental stabilization that prolong a vehicle’s paint life.

What Are the Key Benefits of Using Colored Paint Protection Film?

Colored PPF delivers long‑term paint preservation and flexible aesthetics while reducing maintenance. It protects against chips and scratches, resists chemicals like road salt and bird droppings, and often includes hydrophobic topcoats that simplify washing. Available finishes — gloss, matte, satin, metallic, and color‑shift — let you tailor the look without making a permanent change. For owners of premium cars, colored PPF balances appearance and preservation in a way repainting cannot.

Colored PPF benefits at a glance:

- Scratch & Chip Resistance: TPU substrate soaks up impact energy and prevents paint chips.

- UV & Chemical Protection: UV stabilizers and a resilient topcoat reduce fading and staining.

- Aesthetic Flexibility: Pigmented and specialty finishes allow reversible color and texture changes.

- Lower Maintenance: Hydrophobic topcoats shed water and contaminants for easier cleaning.

The summary above highlights core advantages and leads into more specific evidence of value, including resale implications and finish recommendations for different vehicle types.

Different protective and aesthetic benefits compared

| Benefit Area | Protective Mechanism | Result |

|---|---|---|

| Scratch & Chip Resistance | TPU elasticity + film thickness | Fewer paint repairs; preserved factory finish |

| UV Stability | UV absorbers in TPU/topcoat | Reduced color fade and yellowing |

| Chemical Resistance | Topcoat chemistry | Less staining from contaminants |

| Reversible Customization | Pigmented removable film | Non‑permanent color/finish changes |

How does colored PPF preserve vehicle paint and resale value?

Colored PPF acts as a sacrificial layer, taking surface damage so the original clearcoat and paint remain untouched. Cars with well‑installed film and maintained finishes often inspire more buyer confidence, which can strengthen resale value and reduce restoration costs. Premium colored PPF typically lasts 5–10 years with proper care and comes with manufacturer warranties that support long‑term protection claims. In short, PPF is both a maintenance saver and an investment in a vehicle’s appearance and marketability.

What aesthetic enhancements do colored PPF finishes offer?

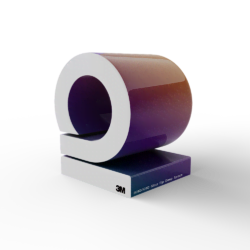

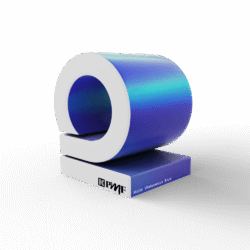

Colored PPF offers a range of looks: high‑gloss for deep, reflective color; matte or satin for understated sophistication; metallic for dimensional sparkle; and color‑shift films that change hue with angle and light. Each finish interacts differently with underlying paint — gloss boosts depth, matte softens reflections, and color‑shift creates eye‑catching drama. Designers pick finishes to complement body lines and lighting: matte accents suit modern supercars, while color‑shift panels highlight sculpted surfaces. All choices remain reversible at removal.

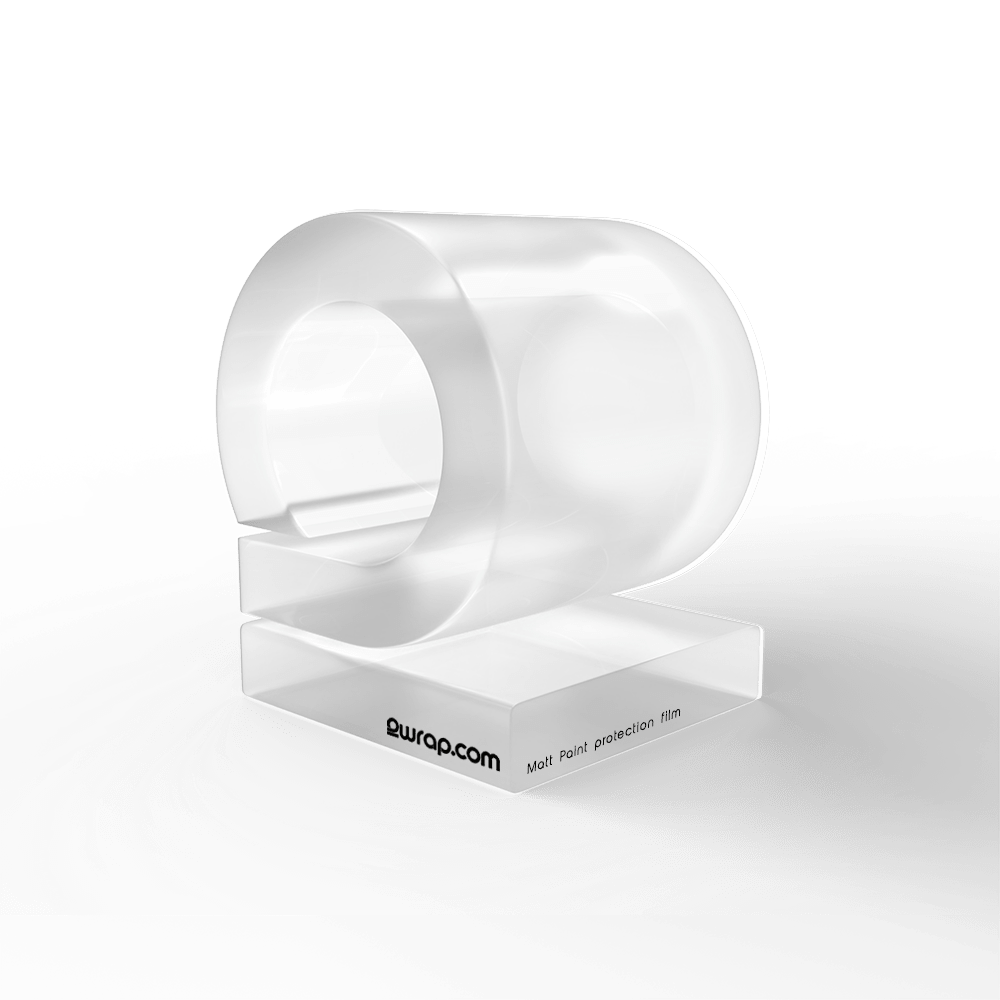

What Types of Colored Paint Protection Film Finishes Are Available?

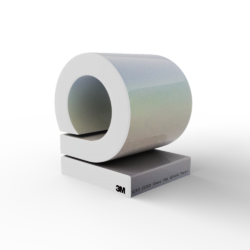

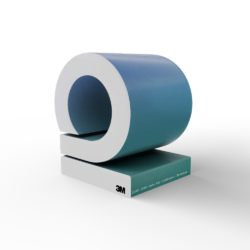

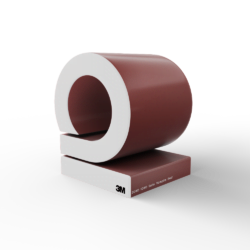

Finishes include gloss, matte, satin, metallic, and color‑shift. Differences come down to topcoat texture, pigment formulation, and optical behavior — factors that determine reflectivity, perceived depth, and how the film wears. Understanding these technical distinctions helps match finish to vehicle design, use case, and maintenance expectations.

What are the characteristics of gloss, matte, satin, metallic, and color-shift finishes?

Gloss PPF maximizes shine and color saturation via clear, high‑reflection topcoats. Matte films scatter light for a low‑gloss finish that hides small imperfections but needs careful maintenance to avoid sheen inconsistencies. Satin strikes a balance with soft luster and easier upkeep than matte. Metallic films add mica or reflective particles for sparkle and depth under directional light. Color‑shift films use layered interference pigments to change hue with viewing angle, delivering a high‑impact, specialty effect.

How do different finishes affect vehicle appearance and protection?

Finish choice affects both look and care. Gloss reveals defects more easily but can incorporate harder topcoats for scratch resistance; matte shows oils and fingerprints and requires matte‑safe cleaners; metallic and color‑shift finishes can mask minor swirls but may need specialized repair approaches to maintain uniformity. Choose a finish by balancing desired visual impact with expected exposure and the maintenance you’re willing to do.

Maintenance tips by finish:

- Gloss: Use pH‑neutral soap and microfiber drying to avoid swirl marks.

- Matte: Skip abrasive polishers; use cleaners made for matte surfaces to keep a flat look.

- Satin/Metallic: Moderate care with non‑abrasive products preserves subtle sheen and sparkle.

These tips help owners align upkeep with finish choice and prepare for installation that yields the best results.

How Does Colored Paint Protection Film Compare to Vinyl Wraps?

Both colored PPF and vinyl wraps change a vehicle’s appearance, but they serve different priorities. TPU‑based colored PPF is engineered for protection and durability; PVC or cast vinyl focuses on visual change and graphics. PPF is generally thicker, offers self‑healing topcoats, and resists abrasion better — making it superior for long‑term paint preservation. Vinyl wraps are thinner, easier for detailed graphics, and often less costly. Choose based on whether your priority is long‑term protection or visual branding flexibility.

Quick comparison summary:

- PPF: Prioritizes paint protection, self‑healing, thicker material, higher cost.

- Vinyl: Focuses on visual change and printing versatility, thinner, easier to replace.

- Why choose PPF: When protecting factory paint is the main goal.

| Attribute | Colored PPF (TPU) | Vinyl Wrap (PVC/Cast) |

|---|---|---|

| Material | Thermoplastic Polyurethane | PVC or cast polymer |

| Thickness | Thicker; more impact absorption (typically 6–8 mils) | Thinner; less impact resistance (typically 2–4 mils) |

| Self‑Healing | Yes (topcoat) | No |

| Lifespan | Longer (5–10 years with warranty) | Moderate (3–7 years depending on care) |

What are the material and durability differences between colored PPF and vinyl wraps?

TPU in colored PPF provides tensile strength, elasticity, and compatibility with self‑healing topcoats that can close fine scratches through polymer reflow. Vinyl wraps are designed for conformability and printability but lack TPU’s self‑healing chemistry and thickness, making them more vulnerable to abrasion and edge lift. Measured thickness and expected lifespans typically favor premium PPF when both are professionally installed, which leads to different maintenance and repair expectations.

Why is colored PPF considered superior for paint protection?

Colored PPF’s advantage comes from its purpose‑built stack: a TPU substrate for impact absorption, a pressure‑sensitive adhesive that peels safely, and a topcoat optimized for self‑healing and chemical resistance. That combination keeps the appearance options while delivering measurable protection against chips and environmental wear that vinyl can’t match. For owners prioritizing factory paint protection — particularly on luxury or exotic cars — colored PPF often provides the best long‑term value.

Which Are the Best Colored Paint Protection Film Brands and Materials?

High‑quality colored PPF starts with TPU films from reputable manufacturers offering durable topcoats, UV‑stable chemistries, and installer support. Installer skill matters as much as material: patterning, heat finishing, and seam placement all affect performance. When evaluating brands, look for non‑yellowing TPU, the finishes you want, and certified installers experienced with luxury and exotic vehicles.

Below is a reference table summarizing common brand-level attributes and material notes for premium colored PPF options.

| Brand | Material / Technology | Notable Finishes / Warranty |

|---|---|---|

| XPEL | TPU with self‑healing topcoat | Gloss, satin; manufacturer warranties up to 10 years |

| STEK | Advanced TPU formulations | Metallic and color‑shift finishes; specialty options |

| 3M | TPU with engineered topcoats | Wide finish range; strong installer network; warranties up to 7 years |

What role does Thermoplastic Polyurethane play in high-quality colored PPF?

Thermoplastic Polyurethane (TPU) is the base material that provides elasticity, tensile strength, and compatibility with self‑healing topcoats. TPU’s polymer structure lets the film absorb impacts and return toward its original shape, while additives provide UV stability and minimize yellowing. TPU also works reliably with pressure‑sensitive adhesives designed to peel without harming factory paint — key for reversible customization. That mechanical resilience and finish compatibility make TPU the standard for premium colored PPF.

Which leading brands offer premium colored PPF options?

Leading manufacturers emphasize different strengths: some focus on vivid specialty finishes, others on durable topcoats or extended warranties. Professional installers typically stock multiple brands so they can match film properties to vehicle use and finish goals. When choosing, prioritize brands that offer the finish you want, documented installer training, and a warranty that fits your expectations.

What Should You Know About Colored Paint Protection Film Installation and Cost?

Professional colored PPF installation requires meticulous prep, precise patterning, and careful finishing — each step affects durability and aesthetics. Cost depends on vehicle size, coverage level (partial versus full), film brand and finish, and installer expertise. Luxury and exotic vehicles typically cost more due to complex geometry and higher risk. Knowing the installation process, typical price factors, and maintenance needs helps you weigh ROI and decide whether to protect high‑impact zones or opt for full‑vehicle coverage.

Installation and cost essentials in brief:

- Preparation: A thorough decontamination and paint inspection are required before patterning.

- Patterning & Cutting: Factory templates or plotter‑cut patterns reduce trimming and seam risk.

- Application & Finishing: Heat shaping, edge sealing, and final quality checks are critical for longevity.

These steps summarize the installation flow and lead into coverage and pricing considerations.

Different installation coverage options and typical pricing factors

| Coverage Option | Typical Scope | Cost Drivers |

|---|---|---|

| Partial (hood, fenders, bumper) | High‑impact zones | Accessibility, labor intensity |

| Full‑vehicle | All exterior painted surfaces | Film quantity, labor time, finish complexity |

| Custom accents | Stripes, roof wraps, details | Fine detail work, finish matching |

What does the professional colored PPF installation process involve?

Installation starts with washing, decontamination, and paint correction if necessary to ensure a pristine substrate. Installers then use factory‑specific or plotter‑cut patterns to minimize trimming and protect edges, applying the film with slip solution, squeegees, and heat to conform to curves and compound surfaces. Final work includes edge finishing, adhesive curing, and a quality inspection to check for contaminants, wrinkles, or lifting. Complex areas like door jambs and mirrors require extra time and skill. Proper execution directly affects longevity and warranty coverage.

How is colored PPF pricing determined and what is the investment value?

Price reflects vehicle size, coverage area, chosen film grade and finish, and installer experience. Partial front‑end packages cost substantially less than full‑vehicle installs, and specialty color‑shift or metallic films often carry material premiums. Evaluate investment value by factoring in avoided paint repairs, reduced detailing time due to hydrophobic topcoats, and stronger resale position from preserved factory paint. For luxury and exotic cars, the protection and preserved finish often justify the upfront expense as preservation insurance.

Cost factors to evaluate:

- Coverage area: More coverage increases material and labor time.

- Film grade & finish: Specialty finishes and premium TPU formulations are pricier.

- Installer expertise: Certified, experienced applicators charge more for complex vehicles.

These points help owners request accurate quotes and compare long‑term value when selecting colored PPF.

What Should You Know About Colored Paint Protection Film Installation and Cost?

Choosing a skilled installer and setting realistic cost expectations are essential for a successful colored PPF result. Owners weigh upfront cost against long‑term savings on paint repairs and detailing — a calculation that often favors PPF for high‑value vehicles where original paint retention matters. 2wrap.com is a lead‑generation and information hub focused on high‑end wrapping and design services, including professional colored PPF installation for luxury and exotic cars, fleet branding, and architectural wraps across California, Belgium, and the Netherlands. A consult with an experienced installer will clarify coverage, material choices, and finishes to achieve the best balance between protection and appearance.

Steps to obtain a quote:

- Consultation: Share desired coverage, finishes, and vehicle details with an installer.

- Inspection: A technician assesses paint condition and suitability for film application.

- Estimate: Receive a scoped quote reflecting film choice, labor, and any prep work.

This checklist helps you move from inquiry to installation with clear expectations and decision points.

Conclusion

Colored paint protection film combines lasting paint protection with flexible, reversible styling — protecting your investment while letting you change the look without permanent paintwork. Choose high‑quality TPU PPF and a trained installer to maximize longevity and appearance. Ready to protect and refine your vehicle? Contact our expert installers to explore finishes, coverage options, and a custom quote.

Referal Letter Aquila Yacht

Referal Letter Aquila Yacht carwrap simulator

carwrap simulator 3D CARWRAP CONFIGURATOR

3D CARWRAP CONFIGURATOR